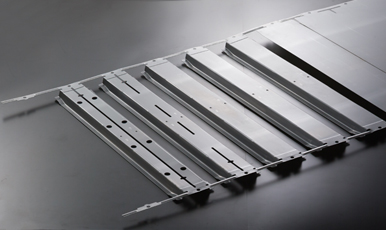

Pressing

Providing press technology critical to the latest automobiles,

from large integrated products to high tensile strength steel and ultra high strength steel

We support a wide variety of sizes, from large products over 1,200 mm in width down to medium and small products with our integrated production system that fully utilizes di-verse press lines and inter-press conveyor robot lines. Our work started early toward the processing of HTSS and UHSS, and it has greatly contributed to modern automobile design that gives first priority to improving safety and reducing weight.

A broad press machine line supporting diverse production

Our transfer presses include a diverse press line from 400 ton to 2,000 ton presses, and we conduct high speed production with the best machining methods, for both large and small products. The 2,000 ton transfer press, which is the largest in the line, is a servo press machine capable of advanced press machining by CNC control, so it can machine even difficult-to-mold products and high tensile strength materials. Hiraoka Body continues to make full use of this equipment and our proprietary machining technology to meet the demands of customers with high precision, high speed machining technology for both thin panels and thick panels alike.

Progressive-Flexible (Progressive mold)

In Hiraoka Body’s blanking lines, progressive-flexible machining is performed on 2 lines. Our company’s progressive flexible line is equipped with a level feeder capable of flexible machining from narrow width to broad width materials, and can support high tensile strength materials. Using this property, we produce complex shaped products quickly and at low cost.

Metal Molding Technology

For many years, Hiraoka Body has demonstrated its strength in manufacturing undercarriage automotive parts. Undercarriage products are large parts that comprise the chassis, and singlehandedly receive stress placed on the car body, and they are a field that requires advanced machining technology, such as extensive use of thick panels and high tensile strength steel. By fusing the metal molding technology cultivated with such difficult products and advanced simulations, and using our manufacturing system integrated with metal mold manufacturers, Hiraoka Body is capable of quick, high performance production, and so we work towards new technology every day.